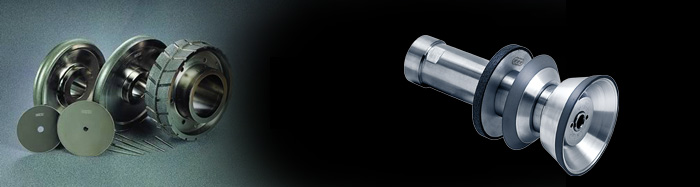

Diamond And CBN Electro-Plated Wheels and Tools

|

||||||||||||||

|

* Help & Support Call Us on 01902 368 624 *

Learn all about Diamond And CBN Electro-Plated Wheels and ToolsPBR Diamond & CBN Electro-Plated wheels and Tools are available in a wide range of forms and contours. Diamond and CBN Electro-Plated Wheels provide high stock removal and high efficiency for free cutting of Hardened Steels, Non Ferrous Metals, Ceramics and Composite Materials. DIAMOND SUPERABRASIVES Diamond is the hardest material known to man and has unsurpassed resistance to wear. Industrial diamond used in wheels will either be natural or synthetic. Diamond superabrasive grinding products have been developed for high precision and difficult to grind applications and materials which include Ceramics, Carbide, Glass, Stone and sintered materials. The requirements for higher quality, longer life and faster grinding cycles from machine tools are the key reasons for using superabrasives with traditional grinding wheel products. Diamond superabrasives are available in a wide range of grit sizes.

Electroplated wheels often use grit sizes considerably coarser to achieve greater metal removal when grinding carbide. Diamond wheels are manufactured in 4 concentrations 50/75/100 and 125. 100 concentration is equal to 4.4 carats of abrasive per cubic centimetre. Other concentrations are proportional. Most commonly used shapes are readily available and non-standard products can be manufactured to suit specific applications. BOND TYPE This is dependent upon the application and we request as much application detail as possible to allow us to recommend the most suitable bond. CBN SUPERABRASIVES CBN (Cubic Boron Nitride) is the second hardest superabrasive. CBN superabrasives are made from man-made material and were developed specifically to grind ferrous materials such as Steel, Hardened steel / Tool steels and Steel Alloys. Longer life and faster grinding cycles are the key advantages when comparing CBN superabrasives with traditional grinding wheel products. CBN superabrasives grit sizes are available as Coarse D181 to D126, Medium D107 to D76, Fine D64 to D54 and Extra Fine D46 to D25. DIAMOND GRINDING WHEELS Diamond grinding wheels are also termed as superabrasives. Diamond grinding wheels are used to grind Carbide, Ceramics, Glass, Fibreglass and Stone. Grit size is available Coarse D181 to D126, Medium D107 to D76, Fine D64 to D54 and Extra Fine D46 to D25. Electro-Plated Diamond and CBN Wheels and Tools Electro-Plated Diamond and CBN Wheels and Tools have a single layer of diamond or CBN crystals which are bound to the wheel or tool by a layer of nickel. This keeps the abrasive particles in place, but allows them to project out of the bond, creating a very open tool or wheel surface with large spaces between the abrasive particles. As the grit is only single layer a complicated profile or form can be manufactured to customer specification. This product requires no dressing.

|

||||||||||||||

PBR

Abrasives Grinding Wheels Applications: 1. Bench Grinding Wheels 2. Centreless Machine Grinding Wheels 3. CNC Grinding Wheels 4. Cylindrical Grinding Wheels 5. Diaform Grinding Wheels 6. Internal Grinding Wheels 7. Floor Stand Fettling Grinding Wheels 8. Lumsden Machine Grinding Wheels 9. Off Hand Grinding Wheels 10. Optical Profile Grinding Wheels 11. Profile Grinding Wheels 12. Ring Wheel Grinding Wheels 13. Saw Sharpening Grinding Wheels 14. Surface Grinding Wheels 15. Swing Frame Fettling Grinding Wheels 16. Tool & Cutter Grinding Wheels 17. Tool Room Grinding Wheels |

|